Do you know how LEGO parts are made?

Since 1932, when it was created, LEGO has been encouraging and exciting children with its mountable and demountable pieces. Many generations have been and still are inspired by the small “bricks” of the most varied colors and shapes. It is often reported some feat of people who build big figures with the toy. Here at Mega Curioso we already show Erebor's recreation of “The Hobbit”, an 18-wheel, 11-engine crane, eight literary works and even tortoise prostheses, all amazingly made with LEGO parts.

But you who played with LEGO in your childhood, or even play to this day, know how the production of toy pieces made in Denmark works?

There are videos on YouTube that show how the parts are manufactured, which have basically been in the current format since 1958. There are millions of parts produced per hour and two of these videos show the entire production and method of operation of the machines within minutes. From them, you can get a good feel for the technology and automation that surrounds the LEGO factory.

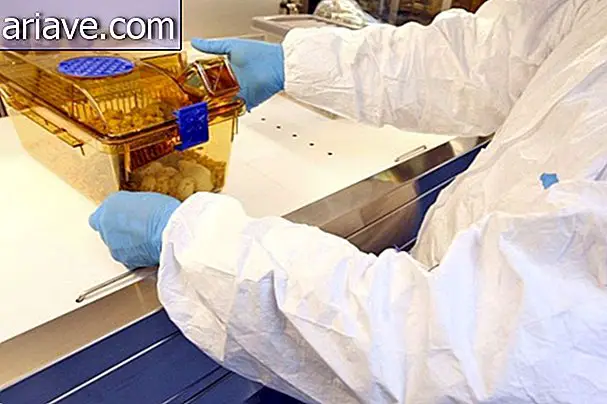

In the first, a report by Bloomberg in 2014, the factory is shown inside and emphasizes not only the technology involved, but the strict quality control of production. In a nutshell, the recording covers the whole process, shows some machines, including a fully automated robot that circulates around the factory, and how quality control and recycling of parts that are not approved in their final form takes place.

The “How It's Made” Channel, on the other hand, features a slightly more complete five-minute video on manufacturing. Production shows factory details and explains, step by step, how tons of granulated plastic become millions of LEGO pieces produced daily.

Also emphasizing all the factory automation where certain sectors don't have a human being wanted, this video reveals interesting production figures. One of the data presented is about the more than one thousand machines that pull the granulated plastic at 232 ° Celsius, shape, cool and drop the parts in the container in just 10 seconds. This process allows LEGO to produce more than 1.7 million pieces per hour and more than 15 billion pieces per year.

In this video, there are also details of a machine that releases more than 15, 000 LEGO doll heads per hour. The yellow base pieces, when ready, are separated to receive the impressions with various facial expressions before being attached to the pieces with their respective bodies. At the end of this process, it turns out that at the time of the recording was coming a "batch" of wizard Harry Potter's LEGO dolls.

The video ends with a brief presentation of the so-called “Legolandia” which has several huge Lego sculptures, which according to the narration, can take up to a month to be ready, even with the help of computers.

If you have some time, there's also an issue of Natinonal Geographic's Mega Factories program, posted by a YouTube user, which also shows production at the LEGO factory.

With over 80 years of existence, the LEGO Group has been one of the leading toy companies since the 1950s. It was at this time that the company's flagship toy, with plug-in parts and the possibility of thousands of combinations, came into its own. concept and be produced on an industrial scale using injectable plastic. With the popularity gained, today LEGO is in more than 130 countries, the company has had its product voted "The Toy of the Century" for more than once.

* Posted on 7/21/2015